Related Posts

THACO Bus: Made-in-Vietnam bus brand reaching ASEAN level

- Published On: 25th June 2025

After more than 20 years of development, THACO Bus has established itself as a national bus brand, pioneering in improving quality and setting new standards for the passenger transport industry in Vietnam. Not stopping at the domestic market, the buses researched, designed, manufactured, and distributed by THACO AUTO are gradually cultivating their presence in international markets.

THACO Bus new-generation products

Modern industrial foundation

Identifying product research and development (R&D) as the key to enhancing competitiveness and sustainable development, THACO AUTO established an R&D Center at its THACO Bus Plant, one of the largest bus manufacturing plants in Southeast Asia.

Here, the combination of experienced engineers and modern design processes has created a closed ecosystem for product development from market research, technical materials design, to testing and completion. The Center also promotes technology applications, developing smart bus lines suitable for Vietnamese and export standards.

R&D Center boasts a team of experts and highly-skilled engineers, advanced equipment systems, and design and simulation software

Modern production lines

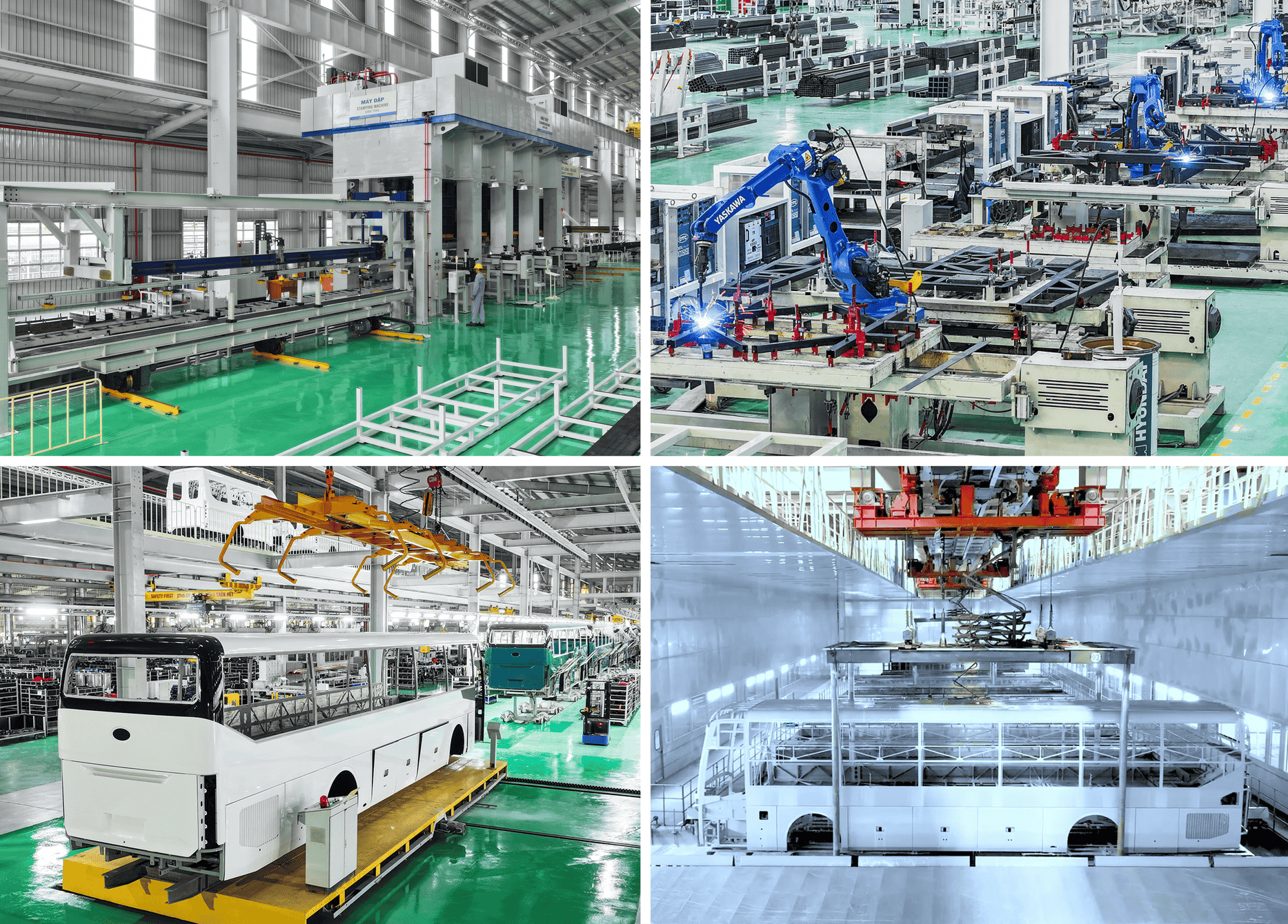

The production lines are highly automated with a series of modern technologies, including: compound pressing lines (1,600 - 6,300 tons) shaping the vehicle body with high precision, robotic welding and laser cutting systems to optimize vehicle’s structure and durability, ED (electrophoretic deposition) coating technology with full body immersion which creates surface uniformity, enhancing car corrosion resistance in all operating conditions. Interior and exterior parts are manufactured using advanced equipment imported from Germany, Italy and Japan, ensuring international quality standards.

The entire production process at THACO Bus is closely monitored by intelligent management systems, Supervisory Control and Data Acquisition (SCADA), Enterprise Resource Planning (MES), and Manufacturing Execution System (ERP), delivering optimized efficiency, real-time quality control, and ensuring every vehicle leaving the factory meets the highest standards. With a local content rate of over 70%, THACO Bus masters the supply chain, flexibly meeting the needs of Vietnamese and foreign customers with highly competitive products.

Compound pressing, welding, ED coating immersion, and product testing lines at THACO Bus Plant

Diverse product range to meet all customer needs

THACO Bus's product portfolio is developed diversely, fully meeting passenger transport needs, from fixed-route transportation, contract vehicles, employee shuttles, to high-end tourism and travel vehicle lines. Notable are the THACO Cruizer seating bus (20 - 47 seats) and the THACO Mobihome 120 sleeper bus (22 - 36 beds), highly rated for their quality, convenience, and operational efficiency.

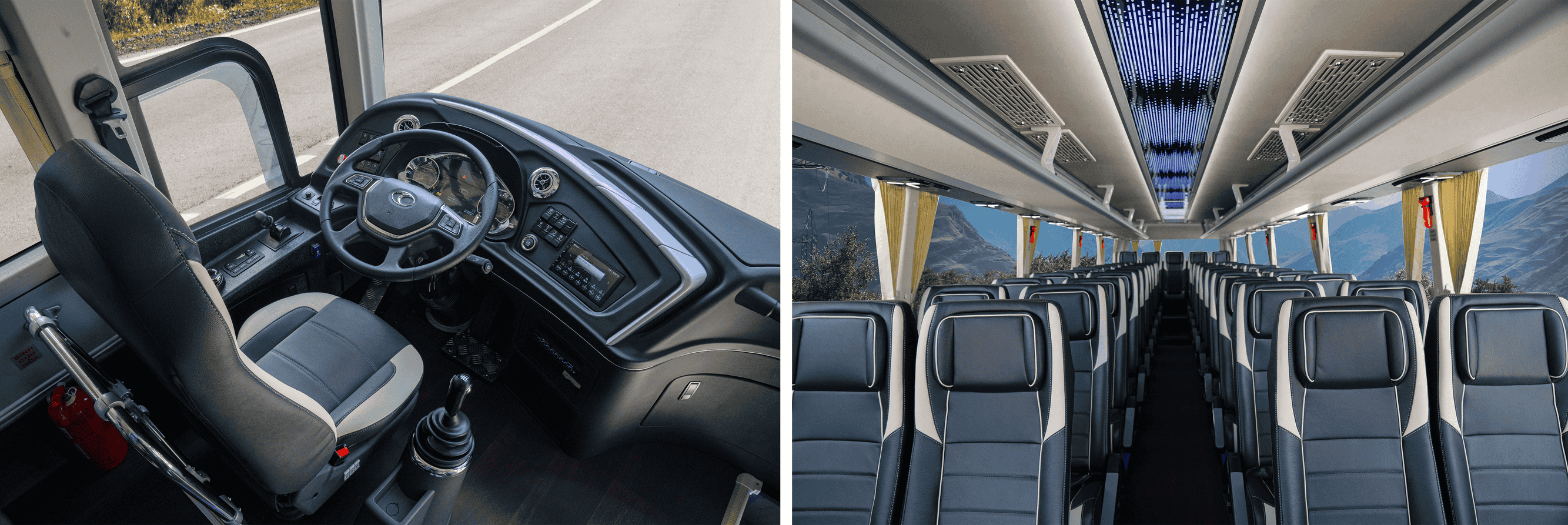

THACO Cruizer owns modern cockpit and a luxurious passenger cabin

THACO Mobihome S 120 equipped with many utilities, convenient passenger cabins

THACO Mobihome S 120 equipped with many utilities, convenient passenger cabins

The buses boast modern design in every detail, convenient and comfortable interiors, powerful operating capabilities, fuel efficiency, and advanced safety technologies, helping transport businesses improve their operational efficiency and service quality.

Vietnamese brand reaching ASEAN level

With outstanding production capacity, stable product quality, and a nationwide service system, THACO Bus has been honored with the Vietnam Value title 6 consecutive times.

The brand has been expanding its presence in the ASEAN market, exporting various buses to the Philippines, Thailand, Myanmar, and Singapore. This not only solidifies THACO AUTO's design and manufacturing capabilities but is also a strategic step to bring Vietnamese bus brands to the global automotive value chain, contributing to enhancing Vietnam’s automotive industry on the international map.